PHESSIO TURBO SPECIALIST MACHINERY

High accuracy of PHESSIO turbochargers derived from each element, With our unremitting efforts plus considerable investment in specialist machinery, PHESSIO TURBO has become a very named brand in R&D, marketing, production and sales service at home and abroad.

HSC 20 LINEAR 5 AXIS IMPELLER MACHINES

The newest 5 axis impeller machines compact, precise, process reliable with >2 gacceleration and spindle speeds up to 60.000 1/min.

HSC machining with surface qualities of up to Ra < 0,1 μm with best contour and fitting accuracy.

Compact 5-axis portal machine in gantry design with integrated NC swivelling / rotary table (A- / C-axis).

Highest dynamic with >2g acceleration and absolute longterm stability.

Integrated linear magazine PH 10 | 100 with max. 99 pallet places (max. 10 kg handling weight)

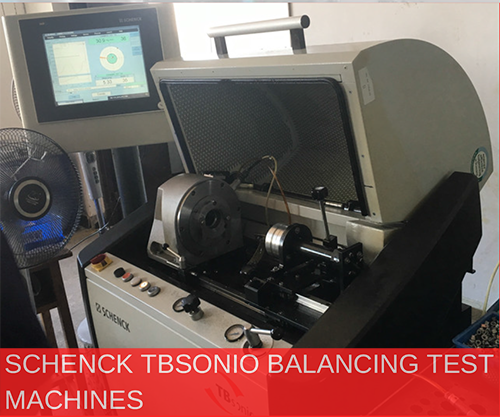

SCHENCK TBSONIO BALANCING TEST MACHINES

The turbocharger CHRA(the complete core assembly) is a complex piece of machinery which has been designed to operate at temperatures up to 800°C whilst reaching rotational speeds in excess of 230,000rpm.

Only VSR(Vibration Sorting Rig) balancing test machine measures imbalance to the speeds necessary to be an effective test, If this balancing process is not carried out, the result can be a turbo which will be noisy in operation and is very likely to suffer failure prematurely.

CROMA COORDINATE MEASURING MACHINES

Coordinate measuring machines (CMMs) are mechanical systems designed to move a measuring probe to determine coordinates of points on a workpiece surface. They provide precise measurements of turbo parts for design, testing, assessment, profiling, and reverse engineering.

The CROMA series, the result of technology of HEXAGON METROLOGY that is the biggest 3D-CMM GROUP, is the precise-3D CMM with powerful performance

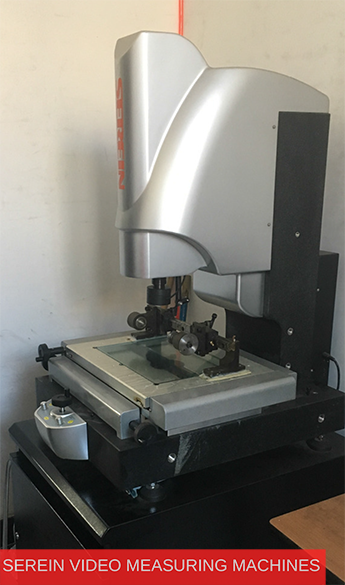

SEREIN VIDEO MEASURING MACHINES

Video measuring instrument is a compact, portable system for manual turbocharger parts inspection, measurement and documentation of small turbocharger components.

The SEREIN series, also Part of Hexagon Group, achieves high precision through precise position control which is most necessary in turbo parts inspection.

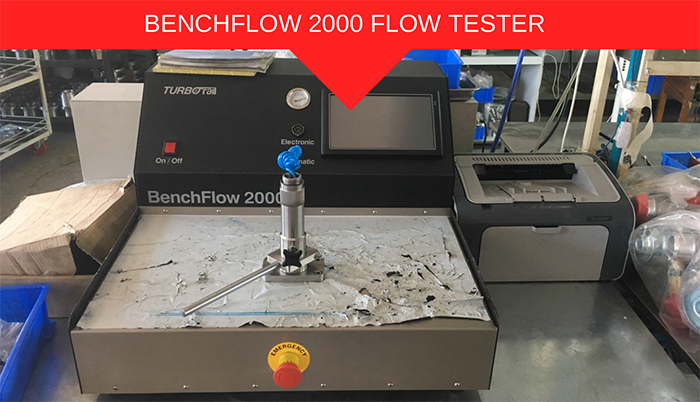

BENCHFLOW 2000 FLOW TESTER

The TSL BenchFlow 2000, the world’s first commercial bench top flow

tester for calibrating variable nozzle turbochargers. this compact machine has many features, such as automatic correction for altitude, humidity and temperature. Pneumatic and electronic actuator drivers as standard.

Each piece of PHESSIO turbochargers would past test on this machine beforeing sending.