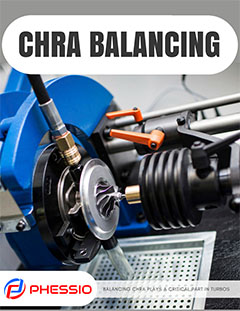

Why Must Do Turbocharger CHRA Balancing Test?

It is vital that to do CHRA balancing test for assembling a turbocharger, The turbocharger CHRA is a complex piece of machinery which has been designed to operate at temperatures up to 800°C whilst reaching rotational speeds in excess of 230,000rpm (that’s over 3,800 revolutions per second!).

To operate under such extreme conditions each component in the turbocharger, which make up the main rotor in the CHRA, is manufactured to some of the tightest tolerances in the automotive industry (as low as 0.002mm). The turbine and compressor wheels are also precision engineered and balanced on specialist equipment as part of the manufacturing process. However, when the rotor is assembled, the accumulation of the remaining tiny imbalance in all the parts can create a rotor, which is out of balance, and will vibrate at critical speeds within the CHRA operating range.

To ensure these CHRA do not vibrate excessively during operation,they must be balanced on a high speed balancing machine which is capable of accelerating the CHRA through its full operating speed and measuring the vibration as the rotor passes through resonant frequencies.

Only the VSR machine measures imbalance to the speeds necessary to be an effective test, If this balancing process is not carried out, the result can be a turbo which will be noisy in operation and is very likely to suffer failure prematurely.