Cartridge

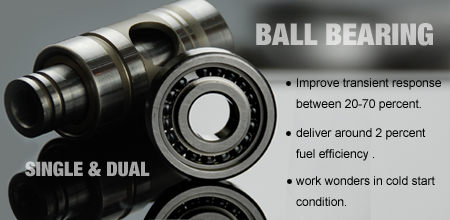

Ball Bearing Kit

Cartridge Ball Bearing are becoming more commonplace, especially in passenger vehicle segment, because of their fuel efficiency and performance benefits and the contribution they make to meeting environmental standards.

Cartridge ball bearing improve transient response between 20%-70%, deliver around 2% fuel efficiency and work wonders in cold start condition.

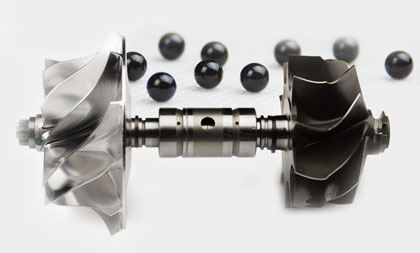

Single Ball Bearing

The first stage of cartridge ball bearing kit, this consists of replacing the compressor side journal bearing with a single angular contact ball bearing. Since the single bearing can only take thrust in one direction, a thrust bearing is still necessary and drag in the turbine side journal bearing is unchanged. with single ball bearing cartridge the compressor wheel is entirely supported by the ball bearings, maximizing efficiency, performance and durability.

Dual Ball Bearing

The biggest improvement compared with single ball bearing is it uses ball bearing for both sides, that is why called “dual”, The ball bearing cartridge gives better damping and control over the single ball bearing system, allowing enhanced reliability for both everyday and extreme driving conditions, In addition, the opposed angular contact bearing cartridge eliminates the need for the thrust bearing, commonly a weak link in the turbo bearing system.

Full Ceramic Ball Bearing

The great improvement we make so far!

Why ceramic? Dual ball bearing uses hybrid ball bearing, ceramic ball and steel case. this has great performance, but the weekness is the durability. by using ceramic outcase, Full ceramic ball bearing is much more durable and reliable. Of course this is not simply achieved by using ceramic material, there are a lot of things involved like material, tolerance, machining, balancing, lubrication etc..

What Cartridge Ball Bearing Kits We Offer