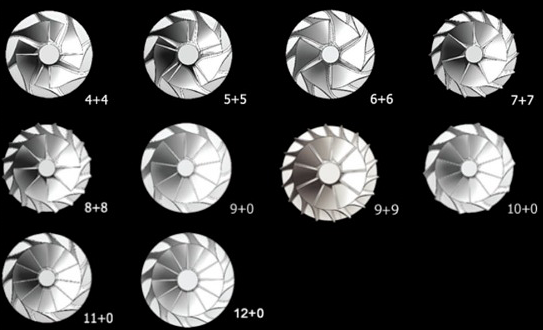

Billet Compressor Wheels

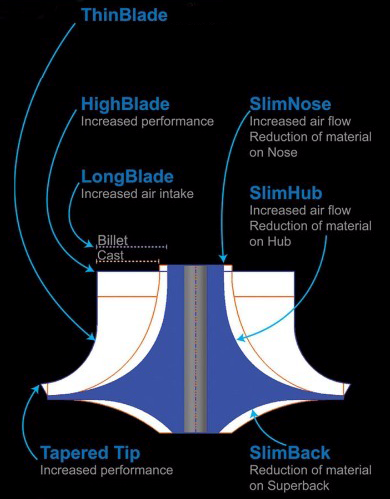

Billet compressor wheels are made from a single block of forged billet aluminum and machined on 5 axis impeller CNC machines to an extremely high level of precision. Replacing a billet compressor wheel will either be used for high dust concentration environments like mining on open cast platforms, or when cast wheels are found to burst from high speed applications.

More Efficiency

Billet construction allows aluminum compressor fins to be much thinner than a cast steel alloy wheel, less blade thickness make a greater efficiency range, the more efficient a wheel is the lower the intake temperature.

More Air Flow

Machined by 5 axis impeller CNC the blades can be designed much more complicated to increase blade surface area, which can flow more air into the engine. Smaller nose and hub allow for a greater blade diameter, High and long blade increase air intake & performance.

More Durability

By using forged billet aluminum to avoid porosity issues, won’t have air bubbles to creat weak spots. it makes billet compressor wheel much more durability than cast compressor wheel.

As a billet compressor wheel manufacturer, PHESSIO TURBO can offer many kinds of size. GET OUR NEWEST E-catalog

We can also do customize billet wheels for you.

Enter your email to get our newest e-catalog.